Home > Urban/suburban design > Sidewalk and hardscape solutions > Engineered soil

Engineered soil

The soil under sidewalks, adjacent to sidewalks, and in sidewalk cutouts is usually compacted to prevent the walk from settling. This prevents many tree roots from growing in soil under the walk. Growth can be severely restricted, creating unhealthy trees, especially in sidewalk cutouts, but if soil is not compacted, the walk will settle.

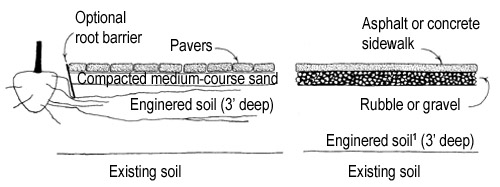

Perhaps the best way to create root space without compromising soil strength for sidewalk support is to use a structural soil or an engineered soil mix beneath the sidewalk as shown below (See: structural soil detail). This strategy appears to be especially beneficial for clayey and loamy soil where compaction beneath walks can become quite severe. One disadvantage of the engineered soil shown below is that settlement could be beyond acceptable standards in the U.S.

The figure below shows a soil mix developed in the Netherlands that supports the weight of pavers placed over the soil, settles very little, meets compaction requirements of engineers and architects (95% of compactability), and provides good growing conditions for roots. This mix is used to replace existing soil before pavers are installed.

The design on the right side of the figure below is proposed for poured concrete or asphalt sidewalks. However, the engineered soil mix presented is not suited for use beneath this surface and it will not support vehicle traffic.

Engineered soil specifications:

- At least 50% of sand-size particles should be greater than 220 µm (M50 should be >220µm).

- D60/D10 < 2.5 where:

D60= sieve size through which 60% of sand passes

D10= sieve size through which 10% of sand passes - Less than 4% (by weight) of soil is of clay-size particles. Clay size particle content should not be less than 2% or Cation Exchange Capacity of the mix will be too low.

- The soil mix should contain less than 1% of particles > 2mm. 5) Organic matter content must be less than 5% (by weight).

Compacted medium-course sand layer:

A sand mix containing a large range of particle sizes compacts best and helps prevent root growth directly beneath pavers.

Rubble or gravel layer:

Particles should be at least 2 inches. No sand or soil should be mixed into the layer. Layer should be 3 to 4 inches thick.

Source: Adapted from E. Couenberg (1994).

1Engineered soil specified above has not be used under asphalt or concrete, only pavers. Consult Grabosky and Bassall (1995) for engineered soil specifications

under pavement.